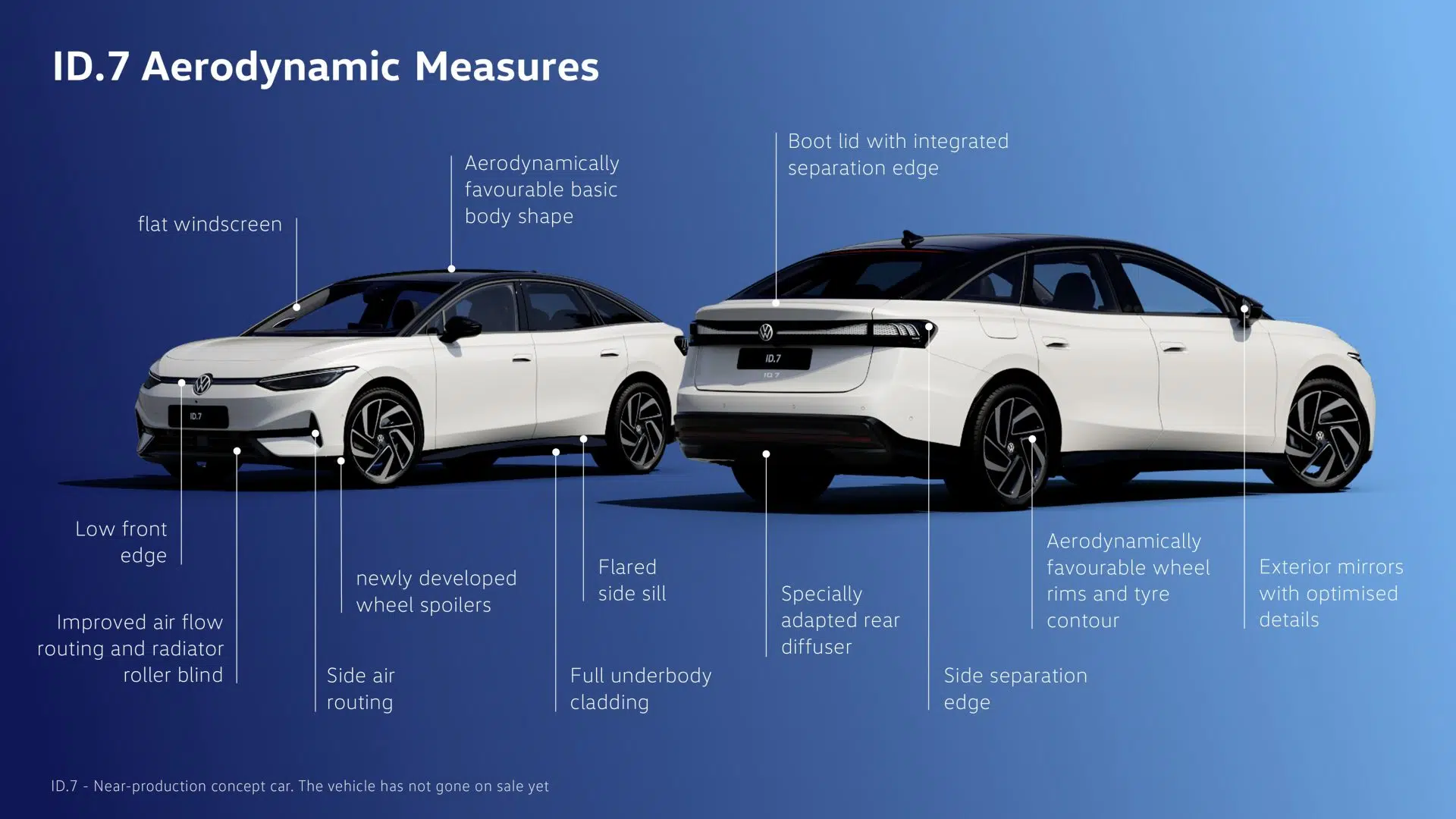

The ID.7 is Volkswagen’s first electric model for the upper mid-sized class, boasting a remarkable range of up to 700 kilometers (WLTP), thus making it an efficiency champion. This impressive range is a result of a new generation of drives, as well as superior aerodynamics, which includes a low drag coefficient (Cd value) of 0.23, a frontal area of 2.46 m², and an aerodynamically favorable base form, all achieved through close collaboration between the Design and Development departments.

For vehicles like the ID.7, the body shape accounts for around 50% of the Cd value, while wheels and tires contribute about 30%, the underfloor 10%, and functional openings for air to flow to the vehicle’s radiators also 10%. The aerodynamic success of the ID.7 is apparent when looking at the vehicle’s silhouette, which stretches almost five meters in length. According to Volkswagen designer Daniel Scharfschwerdt, the ID.7’s design placed a significant emphasis on aerodynamics. This is evident in features like the low front end, the smooth transition into the bonnet, the quick windscreen, the coupé-like roof form, and the tapering rear end, all designed for optimal aerodynamic performance.

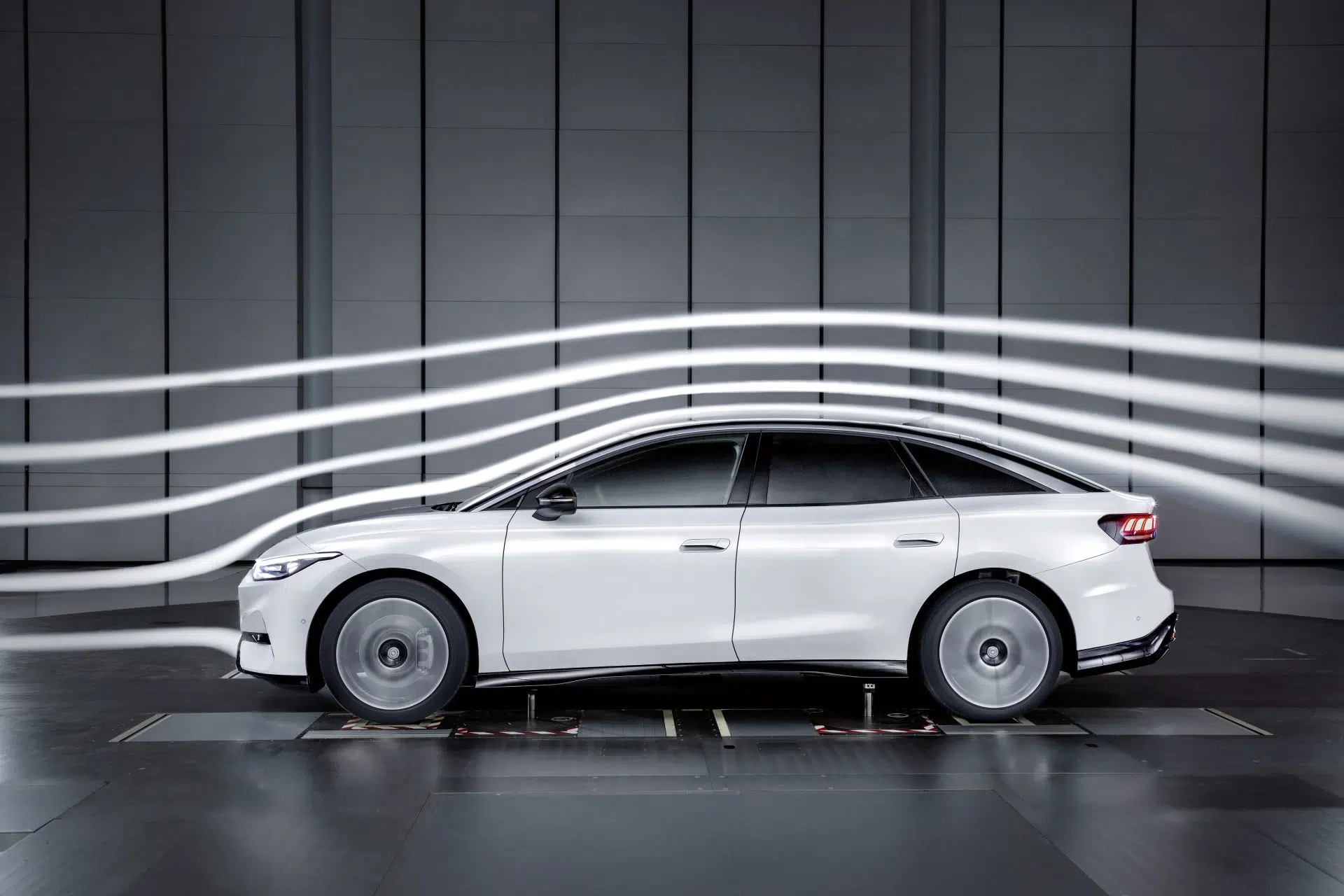

In the early stages of development, the exterior design, underbody, wheels, and other fine details were thoroughly examined. To achieve optimal results, close collaboration between developers and designers was crucial. Project engineer Stephan Lansmann describes their approach as striving for ideal solutions in an iterative process that involves regular consultation between the Development and Design departments, and various small steps that collectively pay off in the end. The development process includes numerous computer simulations for flow calculation, supplemented by wind tunnel tests.

The ID.7 exhibits multiple aerodynamic strengths, including an almost completely closed underbody, newly developed wheel spoilers for the front wheels, air curtains at the front bumper’s sides, flared side sills, small spoilers and trim panels on the underbody. In the ID.7, air flow is actively controlled by a radiator roller blind, which opens only when cooling of the power units and battery is needed. At the rear, aerodynamic efficiency is ensured by the ideally shaped tailgate and the design of the diffuser and side separation edges.

The first year of development focuses on computer simulations with updates every two weeks. The design team provides CAD (Computer-Aided Design) data, and several thousand processors calculate the air flow values. It can take up to one and a half years from the start of development before wind tunnel testing begins. The team uses Volkswagen clay models of the original size of the ID.7 for these tests. Changes based on new findings are made with millimetre precision on these models, for instance, changes to the rear and the separation edges. Prototypes from the 3D printer also help to test numerous variants. This detailed process results in a Cd value of 0.23, which is the best drag coefficient across the entire Volkswagen ID. family.