With the aim of transforming into a leading technology company, in the context of its strategy ACCELERATE, η Volkswagen redefines the Technical Development department in Wolfsburg. This includes transforming the Group department with more than 11,500 engineers into a unit that will set the pace for the transformation of the company. There will be a focus on a complete redesign of the new model development process, with a focus on software (software), customer requirements and the Scalable Systems Platform or SSP, Volkswagen's future electric platform, and a focus on advanced functions rather than individual components. This is expected to reduce development time by around 25%, increase the speed of release of new software versions and also significantly speed up production processes.

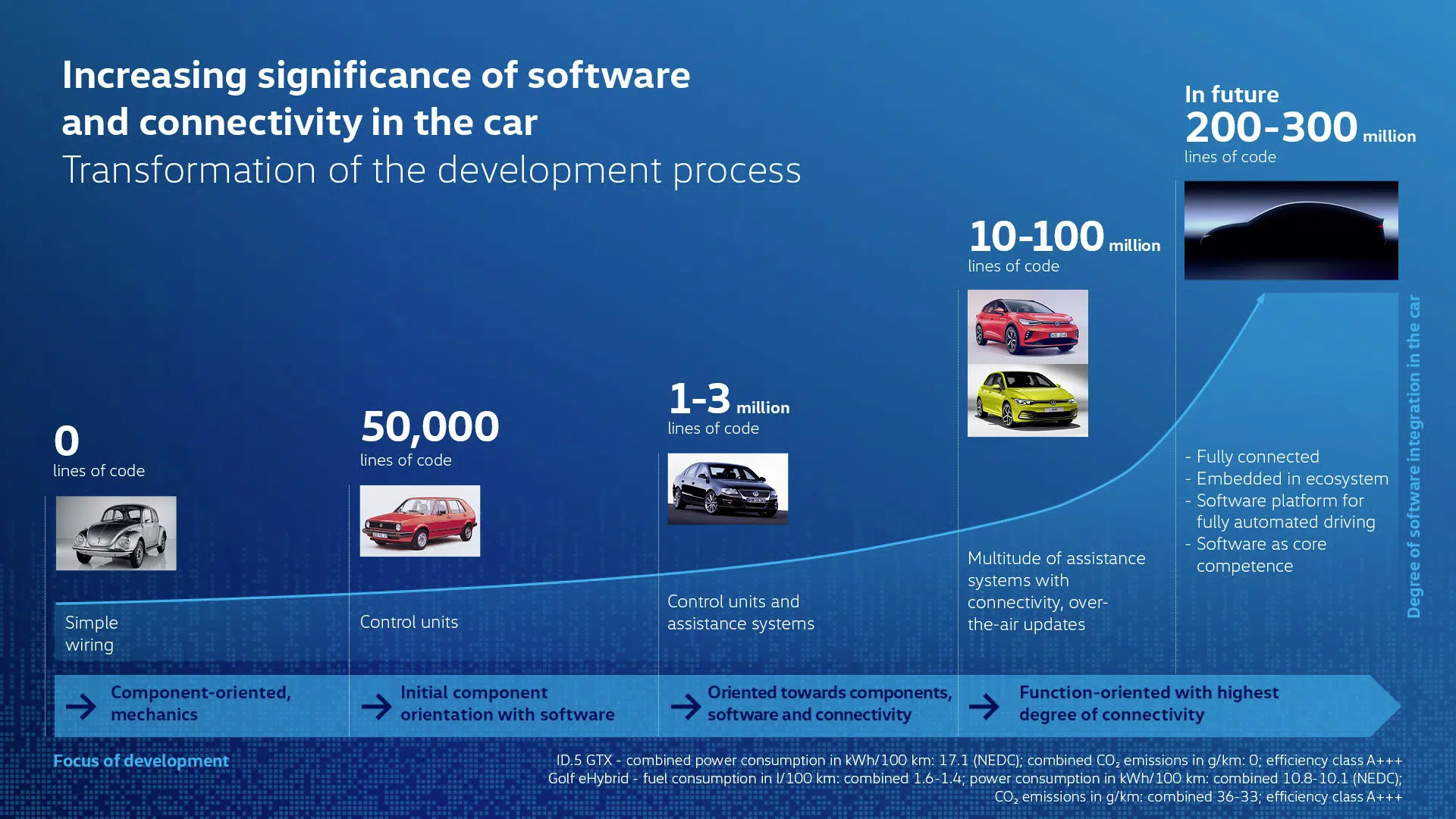

It is significant that a Volkswagen Golf of the last twenty years had software developed with 50,000 lines of code. A modern Passat has 1 - 3 million lines of code, while this figure shoots up to 10 - 100 million lines for a model in the ID family... In the future, with the development of autonomous driving, a car will have software that has been developed using 200 - 300 million lines of code!

"As the car becomes more and more an electrified product characterised by extensive software, then its development must also evolve. We are redefining Technical Development, prioritising software with hardware following. In the future, vehicle projects will be completed in 40 months from the time the basic software architecture is implemented, instead of 54 months today," said Thomas Ulbrich, member of the Board of Management responsible for Technical Development.

The new approach, known as systems engineering, is an approach already familiar in complex development projects in industry, such as aircraft manufacturing. In the 1990s, vehicle development focused mainly on components. As functions and electronics were added in the early 2000s, connectivity began to play an increasingly important role. Now, today and in the future, the vehicle must be seen as just another system in the customer's entire ecosystem and communicate seamlessly with all systems outside the vehicle. To this end, experts from different fields are capturing requirements and interdependencies at an early stage and ensuring that systems and components are configured and designed appropriately so that all these functions can be seamlessly combined.

Volkswagen will invest 800 million euros in the Sandkamp Campus over the next five years. The new, state-of-the-art development centre will raise the bar in vehicle development, housing more than 4,000 engineers and acting as an umbrella for design, concept, user experience, product strategy, model range, technical project management, finance, production planning, quality assurance and sales.

At the same time, Volkswagen is working on the electric platform that the Group will use in the future, known as the Scalable Systems Platform - SSP. A powerful and scalable platform for the electric age, it will be first deployed in 2026 at Volkswagen's Trinity project and will eventually merge the current MEB and PPE platforms. This will make the SSP the foundation for all makes and models - in other words, the basis for more than 40 million Group vehicles - and will enable Volkswagen to consolidate its position as a leading force in electrification. Like MEB, SSP will also be open and available to other companies.