Just before the first race of the year at Hockenheim, BMW Motorsport is already well prepared for the 2017 DTM Championship. Drivers and teams alike have a wealth of experience as they enter the sixth season since BMW's return to the highly competitive touring car championship, and the car will make its first appearance: this year BMW Motorsport is fielding the BMW M4 DTM, which has been developed in accordance with the new technical regulations.

With four titles in three years, the name BMW M4 DTM has become synonymous with great success. Germany's Marco Wittmann won the Drivers' title in 2014 and 2016. BMW Team RMG also won the Teams' title in 2014, while BMW won the Constructors' Championship in 2015. This year is the start of a new era. Given the new regulations, a lot of hard work went into the development of the car beforehand. The BMW M4 DTM now delivers over 500 hp and has undergone extensive modifications to its aerodynamics. Innovative technology has also been adopted in the manufacture of its components.

"We are looking forward to the new DTM season. The numerous changes are aimed at one thing first and foremost: improving the experience for spectators on the track and viewers," said BMW Motorsport Director Jens Marquardt. "I particularly like the new, more powerful cars. In the future, the drivers will make more of a difference behind the wheel and the spectators will get closer to the teams and drivers on track. This combination promises an exciting season in 2017. Our engineers have worked hard in recent months to develop new solutions down to the last detail in the BMW M4 DTM, which is based on the DTM regulations for 2017. I am very proud of the effort of this team. One of the elements that stand out for me is the new look of the BMW M4 DTM. The blue crosses on the headlamps are a design element that originates from the typical BMW 3.0 CSL of the 1970s. DTM enthusiasts will recognise the blue crosses from the 1980s BMW M3 DTM, when they were still present on the bodywork. In 2017, this is done digitally, as with the BMW 7 Series, for example. We are looking forward to the first race weekend at Hockenheim."

Wind of change.

Regulations required BMW Motorsport engineers to take a different approach to aerodynamics in the development of the BMW M4 DTM. The narrower diffuser and increased height from the ground, according to the regulations, limit vertical force and 'dirty air'. The airflow distribution around the car was completely revised. The front bumper now has a completely new shape and is the starting point of the airflow around the car. The exterior mirrors will have a more conventional design again in 2017, in accordance with the regulations. Among the most noticeable modifications are the more pronounced contours of the side channel on the bodywork, the air vents on the rear dome used for the first time and the incredible detail in the rear design.

The rear spoiler is one of the most recognisable elements that have been changed on the DTM cars for 2017. The DRS (Drag Reduction System) has also been altered. Until recently, it featured a single lip that lowered one-way when the DRS was activated. The rear spoiler of the new BMW M4 DTM consists of two lips with the upper one being raised when DRS is activated. Unlike before, the side struts do not move with the wing. The adjustment range of the system has been increased to 40 degrees for 2017, resulting in a higher performance than last year.

The front splitter and the lower part of the DTM cars are standard components under the new regulations. The same applies to the floor, which is 5 mm thicker than before. The rear diffuser also has a completely new shape and is narrower and flatter than on the previous model.

During the aerodynamic development of the new BMW M4 DTM at the BMW Group's Aerolab, the technicians had to achieve better than usual performance: they had just 50 days in which to test the new model in the aerodynamic tunnel and optimise it. Consequently, the CFD fluid dynamics calculations and simulations and the rapid prototyping of components from the computational models of the wind tunnel played an even more important role.

Even more power.

As for the engine, the 2017 DTM regulations allow for a larger diameter restrictor in the air intake, through which the engine is supplied with atmospheric air for combustion. Thanks to the larger orifices - from 2×28 mm to 2×29 mm - the mixture has improved accordingly. This results in an improvement in performance of around 25 hp and now exceeds 500 hp. Given the need for more cooling necessitated by the increased performance of the engine, which is now designated P66/1, the air intakes at the front of the car have been modified accordingly. Due to the higher power, stronger and more durable carbon-fibre brake discs are used in the 2017 DTM.

In its final form, the BMW V8 engine consists of around 800 different components. In total, the engine unit consists of around 4,000 components. In designing the engine for the DTM, BMW took advantage of the expertise of the BMW Group. BMW's high-tech casting plant in Landshut manufactures the large-sized cast components such as cylinder heads and engine blocks. The casting process, coatings and any heat treatment that was deemed necessary were carried out by the specialist departments in Munich.

BMW's power is still transmitted to the track via a 6-speed, serial, racing gearbox with pneumatic 'ear' steering wheel control. Eleven gear ratios are available, allowing engineers and drivers to tailor the transmission to the characteristics of each track and engine when setting up the car.

Innovative technology for even greater performance.

The engine mount is a complex component with a structural role, which carries high loads and connects the engine subframe to the engine itself. It is manufactured specifically for the DTM car by means of 3D printing. BMW Motorsport technicians and their colleagues in the BMW production development departments have been considered pioneers in the field of 3D printing for decades. Together they are developing this production technology for future uses, improving both the efficiency and speed of producing components for racing use. Since 2015, BMW Motorsport has been using a water pump impeller on its DTM engines made on a 3D printer. The high-precision component, which is subjected to high loads, is made of aluminium alloy and has proven its worth in the harsh racing environment.

The chassis of the 2017 DTM cars consists of many standard components: shock absorbers, anti-roll bars, swingarms, hubs and wheel mounts as well as wheel bolts are standard for all. BMW Motorsport technicians have freedom, however, in the side springs and the third front axle element, as well as in the setting and arrangement of the standard components.

The monocoque carbon fibre frame defines driver safety in the new BMW M4 DTM. With an integrated fuel tank, steel safety cage and additional load-absorbing elements in the event of a collision, it provides effective protection for the driver in the event of an accident.

Different conditions in each round.

The cooperation between the chassis and the new generation of Hankook racing tyres is also of great importance. With a new design and compounds, the tyre proposed by the DTM partner represents another exciting element of the coming season. The new DTM slick tyre - the Ventus Race - will offer more grip than its predecessor when in good condition. Unlike that one, however, its performance will drop more quickly and dramatically depending on the driving style. This was the intention of the manufacturers and organisers and will have a big impact on the times at each lap.

Finally, new LED front lights complete the look of the 2017 car, giving it a dynamic look. The rear lights have also been redesigned.

A quick look at the key changes to the BMW M4 DTM.

Hello:

Front lights The blue crosses recall important BMW models from the past for the track and the road: from the BMW 3.0 CSL and the first-generation BMW M3 in the DTM to today's BMW 7 Series.

BMW P66 /1 Engine BMW P66 /1 Larger diameter restrictor nozzles in the intake have increased power to over 500 hp. Consequently, further modifications to the whole followed.

Aerodynamic aids Simpler aerodynamic design elements, in accordance with regulations.

Bumper Redesigned front end with integrated splitter for more efficient airflow, based on changes in aerodynamics dictated by regulations.

Side mirrors Limited aerodynamic design in the area of the exterior mirrors, in compliance with regulations.

Lateral:

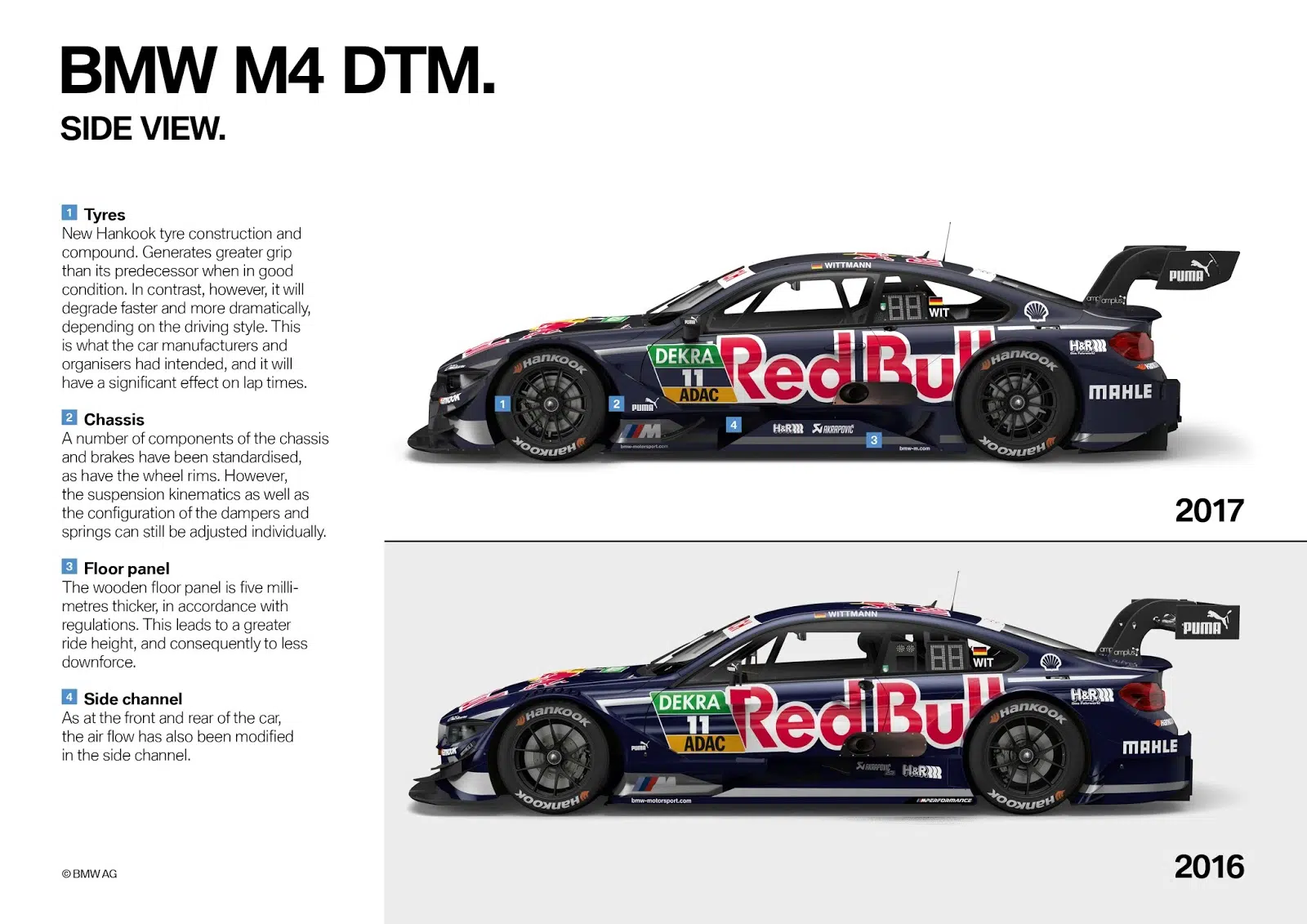

Tyres New Hankook tyre construction and compound. With more traction than the previous one when in good condition. Unlike that one, performance drops more quickly and dramatically depending on how you drive. This was the intention of the manufacturers and organisers and will have a big impact on the times at each round.

Chassis Various chassis and brake components are standard, as are the wheels. However, adjustments to the suspension linkage, shock absorbers and springs are allowed.

Flooring The wooden floor is 5 mm thicker in accordance with the new regulations. This results in a higher height from the ground and less vertical force.

Side channels At both the front and the rear of the car, the airflow through the aerodynamic channels is different.

Back:

Rear spoiler Different DRS. The 2017 spoiler consists of two sections, with the upper section being raised when DRS is activated. The system is more efficient overall.

Diffuser The rear diffuser of the new BMW M4 DTM is narrower and flatter than before in accordance with the new regulations. As a result, it generates less vertical force.

Rear lights The rear light design is based on that of the new BMW M4 Coupé.

Rear bumper Designed from the outset to accommodate the different airflow due to the new diffuser, for example.

Technical characteristics BMW M4 DTM

Dimensions: Length: 4725 mm Width: 1950 mm Height: approx. 1200 mm Weight: 1120 kg (according to the regulation without driver and with weight additions to balance performance)

Engine: Type: 90° V8 atmospheric engine, code P66/1 Capacity: 3999 cc Weight: 148 kg Cylinder diameter: 93 mm Stroke: 73.6 mm Rotation speed: up to 8500 rpm Max. power: > 500 hp Limiting nozzles: 2 x 29.0 mm, according to regulation

Block and cylinder head made from cast aluminium at BMW's casting plant in Landshut. Steel crankshaft, four valves per cylinder controlled by hydraulic lifters, steel camshafts driven by chain drive, fuel injection with low-pressure intake lumen, one injector per cylinder, dry-cartridge lubrication.

Acceleration: 0-100 km/h in 2.6 sec.

Top speed: about 285 km/h

Tank capacity: 120 litres

Context: Carbon fibre monocoque with integrated tank and steel safety cage. Carbon fibre side, front and rear impact absorption elements.

Transmission: standard, 6-speed gearbox with pneumatic control by 'ears' on the steering wheel, 4-speed ZF carbon fibre clutch, adjustable, multi-disc limited slip differential.

Front axle/rear axle: Suspension with double swingarms with knees and adjustable shock absorbers (six settings). H&R springs.

Brakes: Hydraulic, dual circuit brakes, one-piece light alloy calipers, internally ventilated carbon fibre discs front and rear, driver-adjustable brake distribution, solenoid-operated starting valve.

Wheels: Forged aluminium wheels 18" x 12" front, 18" x 13" rear

Ελαστικά: Hankook. Εμπρός: 300-680-18. Πίσω: 320-710-18 (με νέο πέλμα και μίγματα)

Ο Marco Wittmann μιλά για την BMW M4 DTM σε βίντεο.

Κατά τη διάρκεια των επίσημων δοκιμών του DTM στο Hockenheim, ο πρωταθλητής DTM Marco Wittmann ανέλαβε να αναλύσει τις πιο σημαντικές μετατροπές στη BMW M4 DTM.