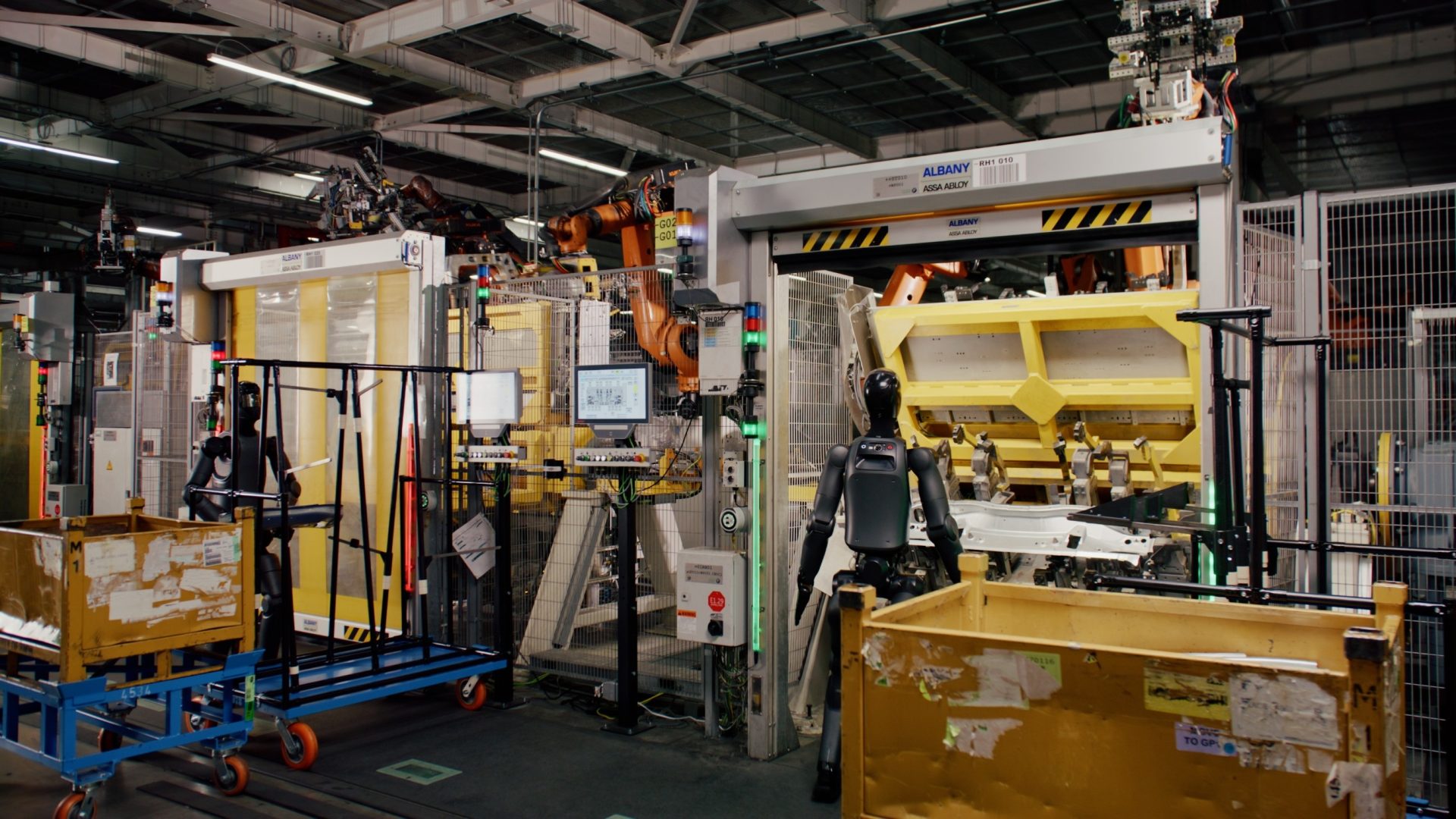

The factory of BMW Group in Spartanburg is a pioneer in the development of production technology, as the company's humanoid robot test has recently been successfully completed Figure from California. This groundbreaking collaboration between BMW and Figure promises to revolutionize the vehicle manufacturing industry by integrating advanced robotic technologies into the production line.

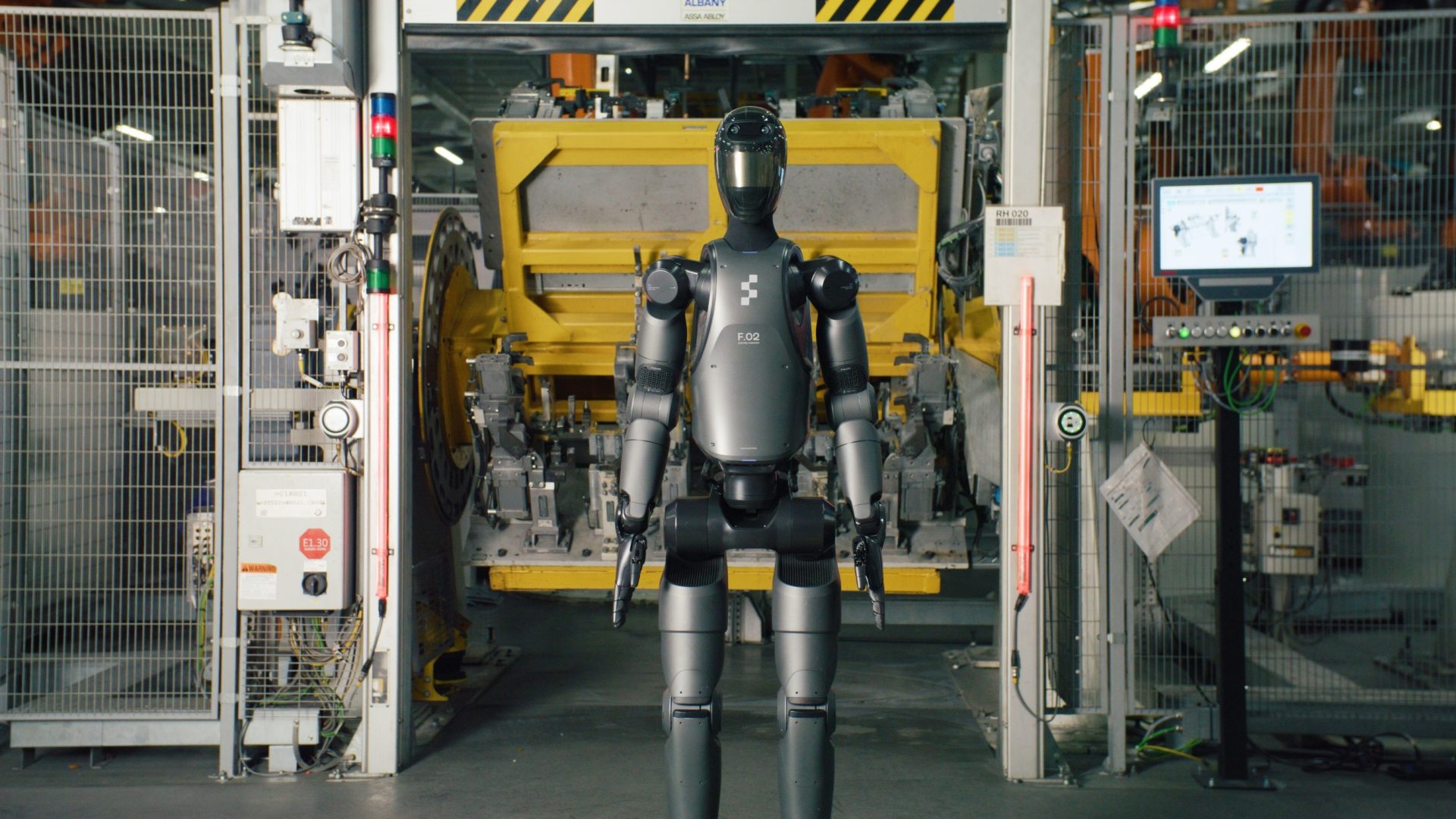

The latest generation of robots, known as Figure 02, has successfully completed its tests in a real production environment, providing important evidence of its efficiency and flexibility. The ability of humanoid robots to perform complex tasks accurately and safely opens up new horizons for the automotive industry, supporting the need for high productivity and quality.

According to the Nedeljković, a member of the BMW Group Board of Management, the definition of possible applications for humanoid robots in production is an important step towards the future. "With the possibilities offered by this technology, we can explore new ways to improve production and efficiency in our factories," said Nedeljković.

The successful implementation of humanoid robots is proof of the BMW Group's commitment to continuous innovation and technological development. The partnership with Figure brings BMW one step closer to the vision of a fully automated production line, where human craftsmanship and robotic technology combine to achieve excellent results.

This development is expected to have a positive impact on the manufacturing sector, providing new opportunities to improve efficiency and product quality, while paving the way for further research and development in robotic technology.

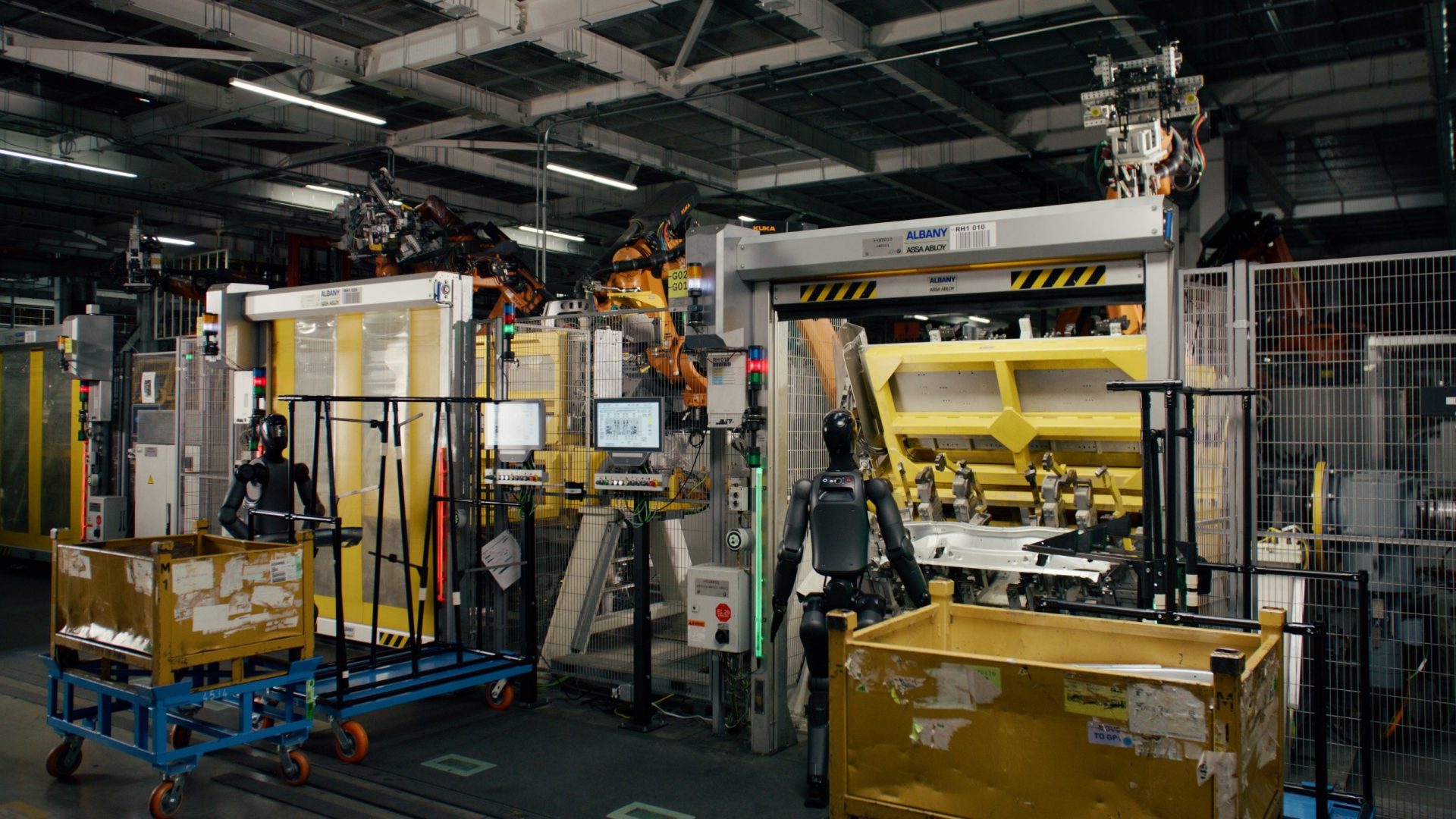

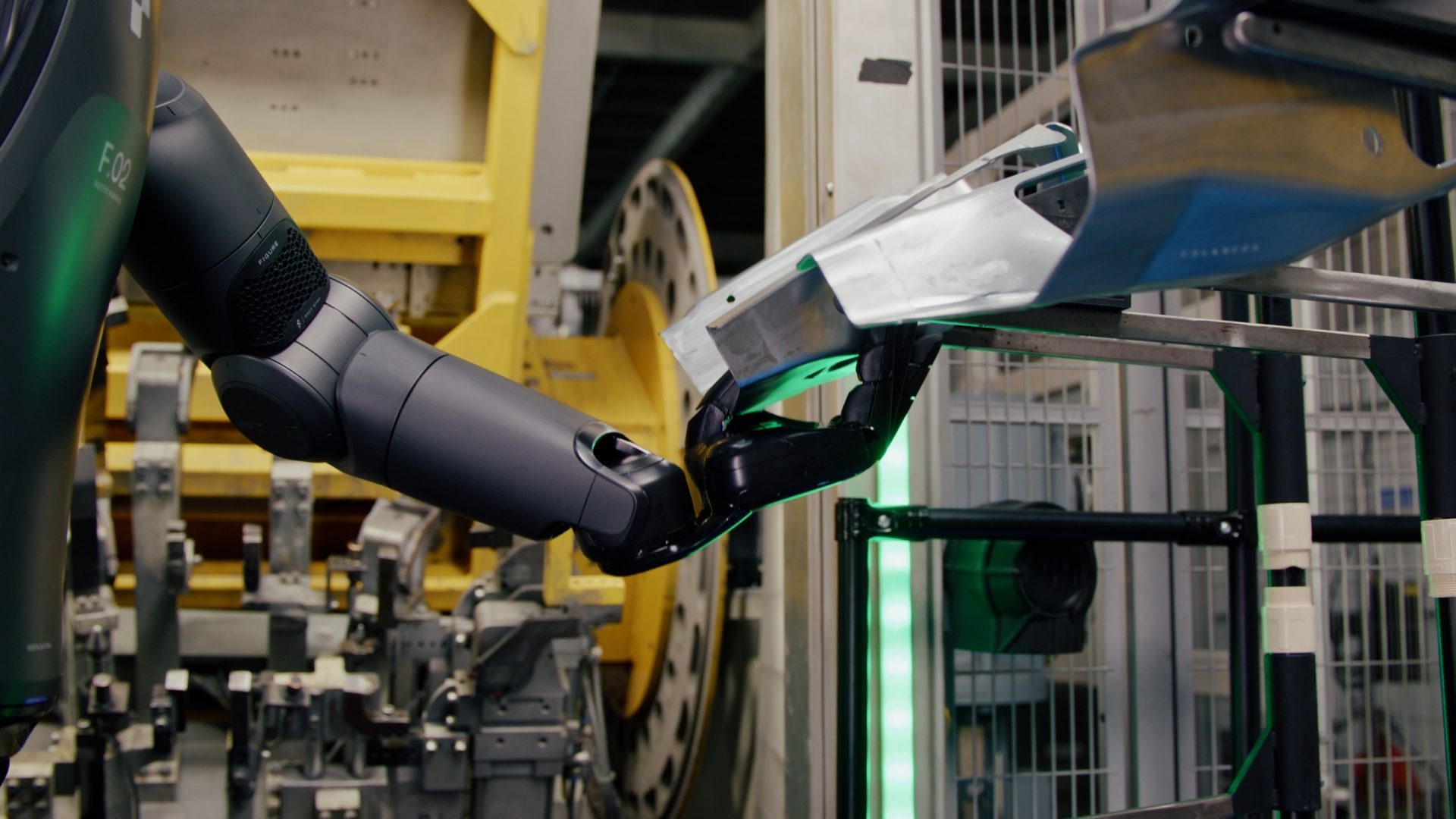

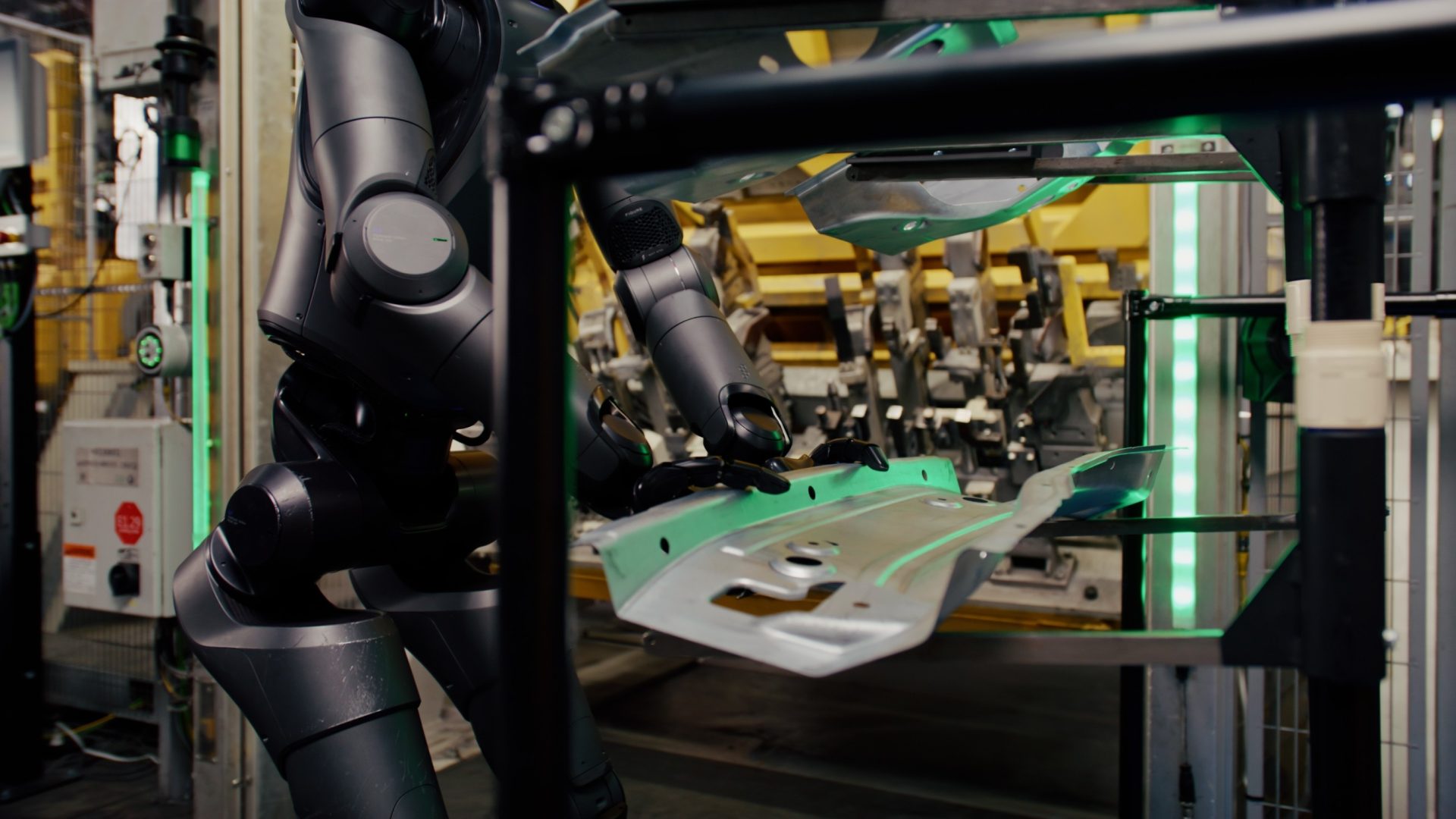

The BMW Group is exploring the use of humanoid robots in production for the first time. During a several-week pilot project implemented at the BMW Group's Spartanburg plant, the latest humanoid robot, Figure 02 from the California-based company Figure, successfully inserted metal parts into specific components, which were then assembled to create the vehicles' chassis. The robot must be highly skilled to complete this stage of production.

At the same time, the use of a robot can free workers from having to perform ergonomically uncomfortable and tedious tasks. Together with Figure, the BMW Group is currently testing and evaluating how humanoid robots can be used safely in car production. This video shows the test run in the body department at the BMW Group's Spartanburg plant: https://b.mw/Figure_02

"Developments in robotics are very promising. With a first test run, we are now identifying potential applications for humanoid robots in production. We want to follow this technology from development to industrialisation," comments Milan Nedeljković, member of the Board of Management responsible for Production at BMW AG.

With the BMW iFACTORY being the vision for the production of the future, the BMW Group is always on a constant search for new technologies. Efficiency, digitalisation and sustainability are key to realising this vision. During the pilot operation, the BMW Group gained valuable insights into the requirements that have to be met in order to enable the integration of so-called multi-purpose robots into an existing production system. This includes how the humanoid robots communicate with the system in real-life conditions. After the first use in car production, experts from the BMW Group and Figure are working together to prepare Figure for future production applications and continue to develop the robots based on the findings.

The Figure 02 incorporates the latest technological developments in robotics.

"We are excited to unveil Figure 02, our second-generation humanoid robot, which recently successfully completed its test phase at the BMW Group's Spartanburg plant. Figure 02 incorporates significant technical advances that allow the robot to perform a wide range of complex tasks completely autonomously," comments Brett Adcock, Founder and CEO of Figure.

According to the California-based company, Figure 02 is the world's most advanced humanoid robot on the market today. The combination of two-legged mobility and advanced dexterity means that Figure 02 is ideal for use in areas with physically demanding, unsafe or repetitive processes, improving ergonomics and worker safety. The Figure 02 features three times the processing power of its predecessor, improved voice communication, better cameras, microphones and sensors, a high-performance battery and fourth-generation human-scale hands with 16 degrees of freedom per hand and human-equivalent strength.

The robot is able to perform tasks completely autonomously - using both hands, just like a human - that require varied and dynamic manipulation, complex gripping and coordination of both hands in combination. It is able to position various complex components with millimetre precision and can walk dynamically using its design capabilities.

Currently, there are no Figure AI robots at BMW Group's Spartanburg plant and no specific timeline has been set for introducing Figure robots to the facility. BMW Group will continue to work with Figure regarding data logging and training capabilities for Figure 02 robots.