The BMW Group has expanded its production footprint in China with the opening of the Lydia plant in Shenyang, China. This major expansion of the BMW Brilliance Automotive (BBA) production base is the latest example of the BMW iFACTORY strategy, and sets new standards in the production of future-oriented vehicles in the era of smart and electric cars. In particular, the Lydia plant opens up new horizons with its innovative digitalisation applications, reaffirming the BMW Group's leading position in the global automotive industry.

"The BMW iFACTORY makes us a standard in the automotive industry. The Lydia factory is digitally born and electrification-oriented," said Milan Nedeljković, Member of the Board of Management of BMW AG in the Production division. He went on to stress: "By responding to our customers' requirements, our production flexibility becomes a benchmark in the competitive environment. The Lydia plant is an excellent example. It is fully capable of producing electric vehicles at a rate of up to 100%. Together with the neighboring plants in Tiexi and Dadong, the Lydia plant will play an important role in accelerating the production of BMW electric vehicles in China."

With a total investment of €15 billion. RMB 15 billion, the Lydia plant is the largest single investment project in the history of the BMW Group in China. Located in the Tiexi District of Shenyang, the plant has all four major production areas (press and body shop, paint shop and assembly line) and increases the annual production capacity at the Shenyang production base to 830,000 units. To meet the growing customer demand for electrification, Lydia's plant is fully flexible to produce electric vehicles at a rate of up to 100%. Production of the all-new BMW i3 - BMW's first all-electric mid-size sports sedan for the Chinese market - began at the Lydia plant in May.

Jochen Goller, President & CEO of the BMW Group in the China Region said: "The expansion of our production footprint in China shows that we are preparing for further growth in the world's largest electric car market and we believe in China's long-term prospects. We are intensifying our efforts in electrification, aiming for over a quarter of our sales in China to be fully electric by 2025. With BMW's expanded and upgraded production base in Shenyang, we are now fully prepared to serve the growing market demand for electrification in China."

"Today is a day of pride for BMW Brilliance and the BMW Group. It marks an important milestone in our successful development in Shenyang City over the past 20 years," said Franz Decker, President & CEO of BMW Brilliance Automotive. "Despite many challenges over the past three years, our new plant in Lydia has been completed on schedule. It is a testament to our strong team in China and an excellent global partnership. The Lydia plant sets the standard for production that is LEAN. GREEN. DIGITAL."

Giving Life to the 'Industrial' Metaverse '

While the Lydia plant follows the BMW iFACTORY strategy, LEAN. GREEN. & DIGITAL, in the area of digitalisation the new plant is truly innovative. With Epic Games' powerful Unreal Engine 3D rendering platform as its backbone, the Lydia plant was the first BMW Group factory to be fully designed and simulated in a virtual environment from the outset with every detail of the entire production process designed virtually. In this way it can be considered a Metaverse plant. Integrating the virtual world with the real world reduced planning time, allowed teams from different regions and time zones to work together, and effectively overcame the adverse effects of the pandemic, which in itself reduced the plant's construction time by six months.

Lydia's factory operations are data-driven: cloud-based digital platforms and the Industrial Internet of Things (IIoT) connect every product, process and person through transparent, always available and embedded data. This extensive use of data science improves quality control, increases efficiency and enables predictive maintenance. With the extensive use of artificial intelligence, data analytics and algorithms, decisions are no longer made according to experience but based on data. Around 100 AI applications are currently in use at BMW's production base in Shenyang.

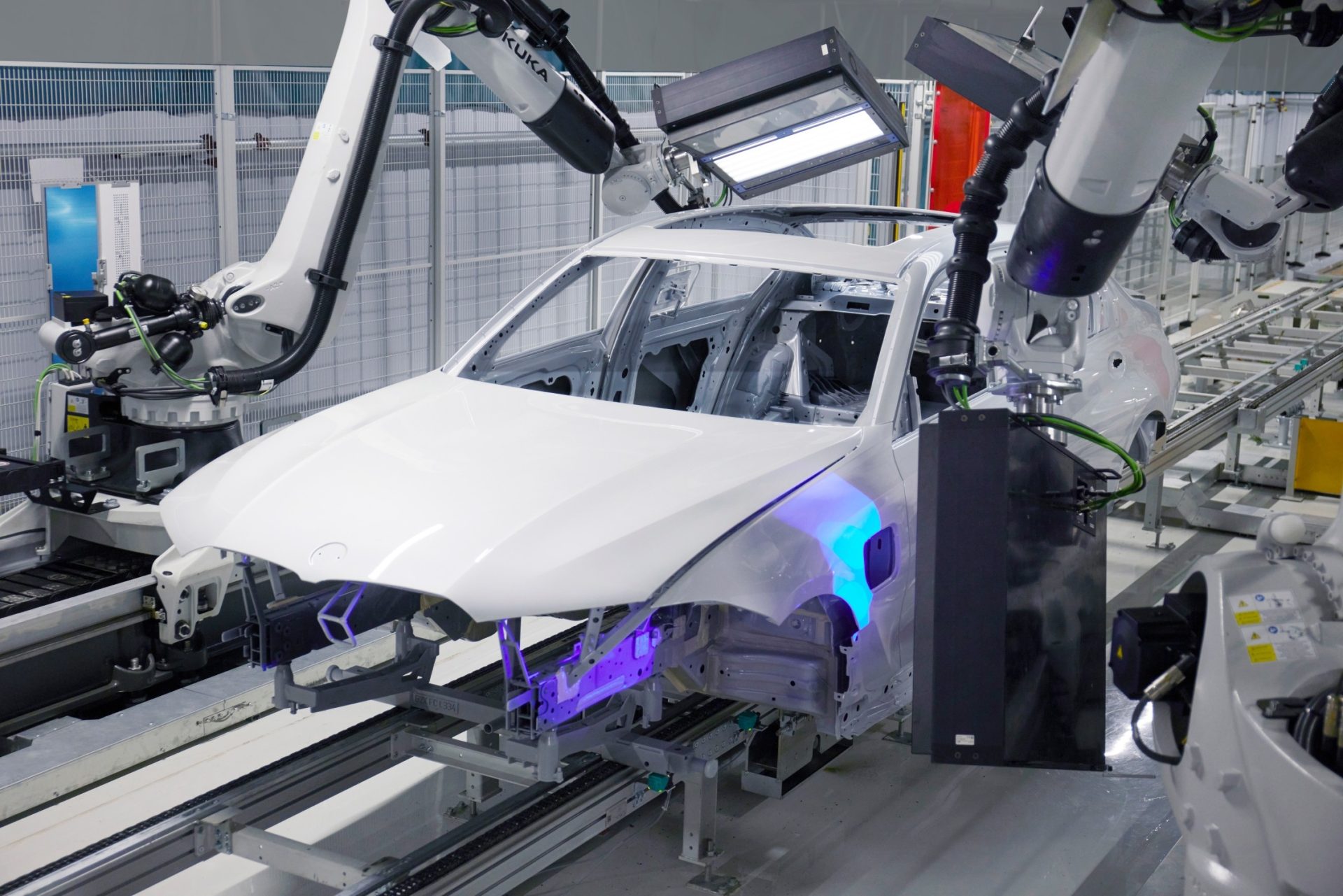

A robust network environment and data processing capabilities are essential for data-driven operation. For example, the 1,600 multifunctional cameras used in quality assurance generate over 10 petabytes of data per year. The entire plant is covered with a 5G gigabit network in order to meet the bandwidth requirements for technologies such as augmented reality (AR) and real-time video transmission. To cope with the huge amount of data, BMW Brilliance also built a new data centre for the Lydia plant containing over 1,200 servers.

Producing cars in the most sustainable way

The BMW Group has set a target to reduce lifecycle carbon emissions per vehicle by 40% by 2030 compared to 2019, which includes a reduction of 80% in carbon emissions at production level. As such, the sustainability philosophy is also reflected in the Lydia plant.

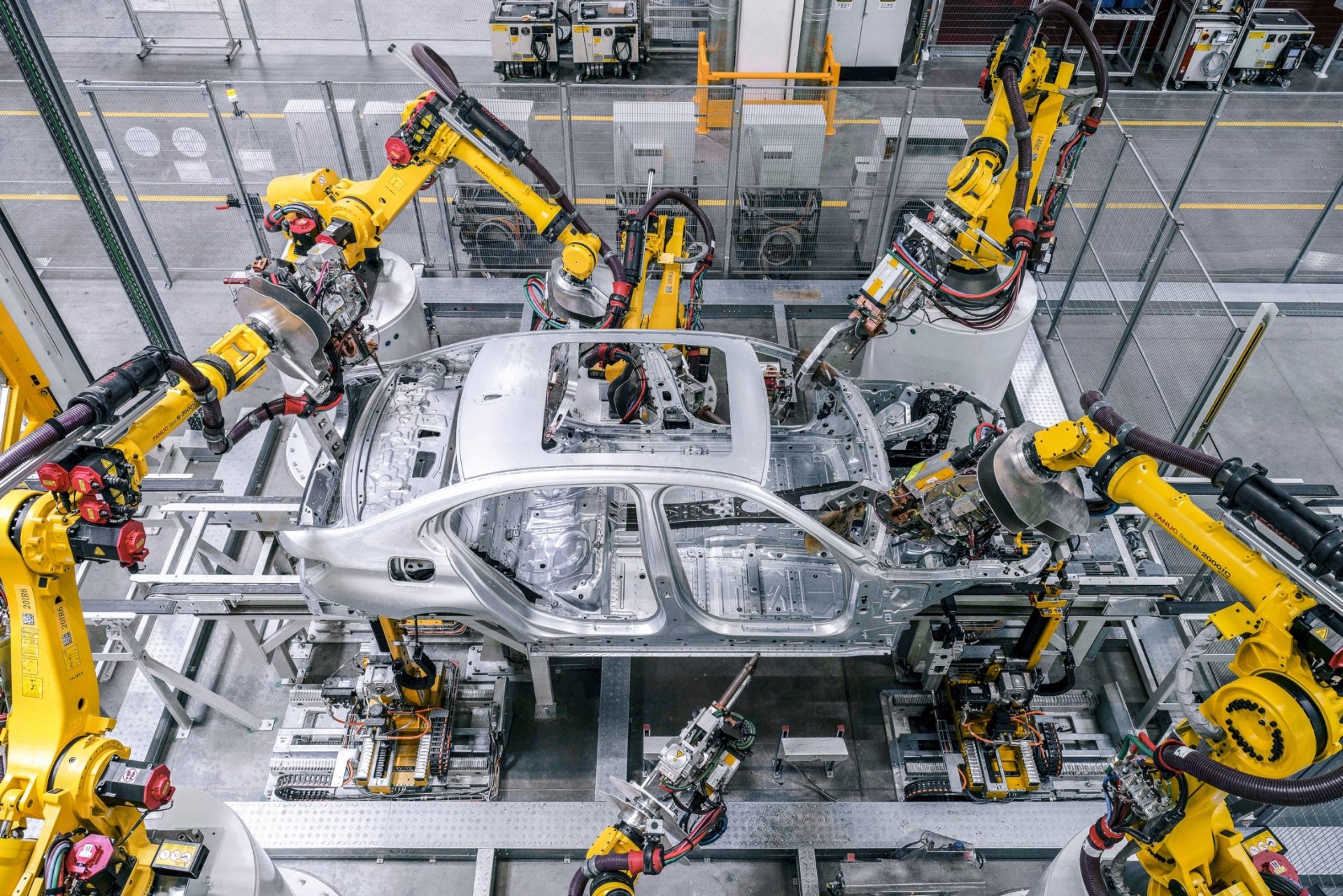

The new production plant uses top-class building materials, such as advanced insulation, to keep the rooms at the right temperature all year round, while reducing energy consumption. The plant's workshops are equipped with state-of-the-art production equipment, such as electric welding guns and furnaces in the Body Department that use electricity from renewable sources to reduce emissions. Lydia's plant also has a dedicated Intelligent Operation Center with an intelligent energy management system that monitors energy and resource consumption in real time and uses artificial intelligence for in-depth analysis of how to optimize energy use.

Currently, BMW's entire production base in Shenyang uses 100% of renewable electricity. It has 290,000 square meters covered with solar panels, ranking it in the top 1η location in Liaoning Province. These solar panels can generate 44,000 MWh of electricity a year - enough to power 9,000 homes for an entire year. The expansion of the solar panels will continue in the coming years, as an area of 120,000 m2 is already under construction at the Lydia factory.

The new car factory in Shenyang also emphasises biodiversity. Its green spaces consist of gardens, artificial ponds, a variety of plants and 11,000 trees, a sustainable landscape, and a system that has the ability to collect rainwater to nourish plants and replenish groundwater.

High flexibility oriented towards electromobility

Flexibility is one of the BMW Group's greatest strengths in production, especially its ability to utilise resources and adapt production to demand at short notice. The Lydia plant is tailored to the production of electric vehicles, but can also manufacture other models flexibly and efficiently.

By the end of 2025, the BMW Group expects to have delivered more than 2 million pure electric vehicles worldwide, with one in four new vehicles sold in China being a pure electric model. By then, BMW's "Neue Klasse" models, representing the next technological leap forward in automotive evolution, will also enter the market. The new Lydia plant and the neighboring plants in Tiexi and Dadong will play an important role in accelerating the production of electric BMW models in China.