The BMW Group supports its mission of sustainable mobility with ambitious greenhouse gas reduction targets: At this year's Annual General Meeting, the company announced that it will reduce CO2 emissions by more than 200 million tonnes by 2030. The company announced today that it will reduce its CO2 emissions by 200 million tonnes by 2030, which is 20 times more than the annual CO2 emissions of a city of more than one million inhabitants such as Munich. To this end, the BMW Group is reducing the carbon footprint of its vehicles throughout their entire life cycle - from the extraction of raw materials, through production and the use phase, to recycling at the end of their life cycle. Moving forward, using fewer natural resources will be a priority.

"A climate-friendly car is not created solely by using green energy. We need to design our vehicles with sustainability in mind from day one: by reducing the amount of material used in manufacturing and, most importantly, by incorporating reuse and recycling schemes from the outset. In view of the rising prices of raw materials, this is not only an urgent necessity on an environmental but also on a business level," said Oliver Zipse, Chairman of the Board of Management of BMW AG, at the Annual General Meeting in Munich on Wednesday, 12 April. "The technological requirements for this are high: That is why it is our desire to become a pioneer on the road to the circular economy. We are already looking at ratios for the use of secondary materials in the 'Neue Klasse' within a clear and ambitious programme to achieve our high goals."

RE:THINK, RE:DUCE, RE:USE, RE:CYCLE - BMW Group makes the circular economy the central theme of the IAA MOBILITY 2021 exhibition

The BMW Group will highlight the future potential of the circular economy for environmental and climate protection at the IAA MOBILITY 2021 in September. The motto "RE:THINK, RE:DUCE, RE:USE, RE:CYCLE" is a holistic approach that rethinks the use of primary raw materials to drastically reduce the use of primary raw materials in the cars of the future.

The BMW Group already intends to give a new, revolutionary dimension to the sustainability of its "Neue Klasse" models from the middle of the decade by significantly reducing the use of raw materials per vehicle. The aim is to substantially increase the proportion of secondary materials from recycled steel, plastic and aluminium. Faced with a shortage of natural resources and rising raw material prices, the BMW Group sees this step as a crucial lever for sustainable business practices and the creation of a clear efficiency obligation.

To achieve this, the BMW Group has initiated a paradigm shift based on a 'secondary first' development philosophy - i.e. the priority use of secondary materials where quality and availability factors allow.

The carbon footprint of high voltage batteries will be reduced over 50%

The high-voltage battery plays a unique role in this: The battery manufacturing and cell production process is highly energy-intensive and therefore contributes heavily to the carbon footprint of any electric car. With the next generation of battery technology to be launched in the "Neue Klasse", the BMW Group aims to reduce the carbon footprint of the high-voltage battery to less than half compared to current Gen5 technology.

In addition to the shift to green energy already being implemented by cell manufacturers, the new battery and cell philosophy, combined with the improved chemical composition of the cell, will also make a significant contribution. It is another factor in the increasing proportion of secondary materials in cells and high-voltage batteries overall. The shell in the BMW iX* already contains up to 30% of secondary aluminium while up to 50% of secondary nickel, which is a key raw material, is used in the battery cell. At the same time, the BMW Group has limited the use of critical raw materials in the current generation of battery cells and has reduced the amount of cobalt in the cathode material to less than 10%. The electric motor no longer requires the use of rare earths.

"Circular design" as a basis for the circular economy

Recycling needs are already being considered from the design phase of the vehicle - because extracting materials in pure form is a primary challenge for current recycling processes. For example, the electrical system must be easily removed before recycling to avoid mixing steel and copper from the vehicle's wiring. Otherwise, the secondary steel no longer meets the strict safety requirements of the automotive industry. The use of monomeric materials - for example in seats - must be increased significantly in order to maximise the recycling rate.

Another key element is the possibility of efficient dismantling. For secondary materials to be competitive in the marketplace, the vehicle and each component must be dismantled quickly and economically before recycling. Pre-requisites must be decided at the design stage of the vehicle - for example, not to secure the joints with glue, but to design them so that they can be removed at the end of the vehicle's life cycle, and at the same time to ensure that the different materials do not mix with each other.

CO2 reduction targets adopted by the Science-Based Targets Initiative - all production will become climate neutral (carbon neutral) by 2021

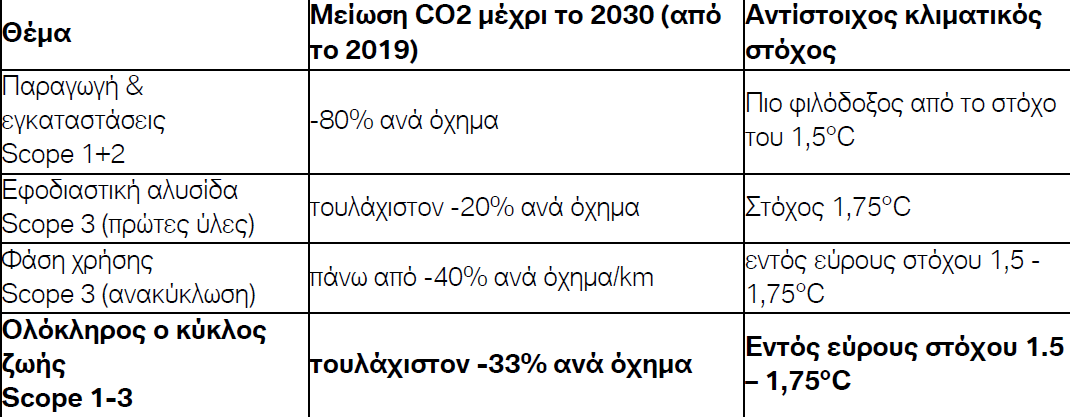

The BMW Group has put sustainability and energy efficiency at the heart of its strategic direction in 2020 and, with this realignment, is pursuing a much more ambitious course than the goal of limiting global warming to two degrees. Throughout the vehicle life cycle and taking all three Scopes into account, the BMW Group has set measurable and verifiable targets that have been endorsed by the Science-Based Targets Initiative (SBTi):

Each of these targets represents a significant reduction in pollutants - in other words, a real reduction in CO2 emissions per vehicle. A key factor is that production and all BMW Group facilities will be operated exclusively with green electricity from the end of 2020. Starting in the new year, the BMW Group is also offsetting residual CO2 emissions (Scope 1+2) through selected offset measures, which additionally cover emissions from company cars and business travel, for example. This means that from 2021 onwards, the entire production of the BMW Group, including its facilities worldwide, will be completely carbon-free (climate neutral).

For the BMW Group, one thing is certain: Such measures are important in terms of offsetting the impact of harmful air pollutants - however, this does not mean that other measures that offer real reductions in emissions should be substantially delayed. For this reason, the BMW Group only applies these measures to residual carbon emissions that remain unavoidable - for example from the use of highly efficient cogeneration plants. "As far as the BMW Group is concerned: avoidance is preferable to compensation. In this way we have already reduced energy consumption per vehicle produced by more than a third from 2006 levels and we can even reduce the corresponding CO2 emissions per vehicle produced by more than 70%," said Zipse.

The BMW Group is the first car manufacturer to set clear targets for reducing CO2 emissions in its supply chain by 2030. In addition to the use of green energy for the energy-intensive production of fifth-generation battery cells, other measures have been put in place - for example, solar energy will in future be used for the production of aluminium, which also has high energy requirements. In addition, the BMW Group is investing in an innovative method for CO2-free steel production developed by the US startup Boston Metal through its investment arm, BMW i Ventures.

2030: At least 50% of global sales will consist of pure electric vehicles

A key driver for decarbonising personal mobility and the most important factor in reducing CO2 emissions in the use phase will be the expansion of electromobility - which the BMW Group has developed even further in recent years. The company will offer five all-electric models by the end of the year: the BMW i3*, MINI SE* and BMW iX3*, as well as the two key flagship innovations, the BMW iX* and BMW i4*. In the coming years, this will be followed by all-electric versions of the BMW 5 Series and BMW X1 - high-volume sales models. These will be joined by the BMW 7 Series, the successor to the MINI Countryman and other models. By 2023, the BMW Group will offer at least one all-electric version for the 90% or so of its categories on the market.

Between now and 2025, the BMW Group will increase sales of its all-electric models by an average of well over 50% per year - ten times more than in 2020. Based on current market forecasts, the company estimates that at least 50% of its global sales will consist of all-electric vehicles in 2030. The actual figure may vary significantly from market to market and will largely depend on the progress made in expanding infrastructure in the region.

At this point in time, there will be no category in the BMW Group's entire product range in which the company does not offer at least one all-electric model. In fact, there will be categories that will exclusively offer pure electric models. The company, will also be able to manage a much larger proportion of pure electric vehicles if there is a corresponding demand. In total, over the next decade, the BMW Group will bring around ten million pure electric cars onto the roads.

Definition CE 04 - Production electric vehicle to be unveiled this summer

BMW Motorrad is also expanding its range of electric two-wheelers for urban areas: At the #NEXTGen 2020, the company shared with the public the BMW Motorrad Definition CE 04, its tangible vision of a new kind of urban electrification, both in terms of technology and design. The BMW Group will present the corresponding production model this summer.